717-355-2008

Mon-Fri : 8am–5pm

Mon-Fri : 8am–5pm

Meet our Open-End Dumpster, the ultimate sidekick for handling bulky, awkward, or oversized loads with zero hassle.

Available in both standard and low-profile designs to fit beneath workbenches, these open-end self-dumping hoppers allow you to unload long waste or stock materials without the limitations of trash cans or hand-loading.

In fast-paced manufacturing environments, efficiency is everything. Our open-end dump hopper is designed to handle bulky, oversized materials like scrap metal, wood, and production waste with minimal effort. Its open-ended design allows your team to quickly load and unload long or irregularly shaped materials without struggling to fit them into a confined space.

This means less time spent on waste handling and more focus on production!

Built for seamless integration into industrial and woodworking workflows, this hopper features smooth-rolling casters for easy mobility and a forklift-compatible structure for fast and efficient transport across the facility. The rear-mounted latch allows for safe, controlled, and EASY dumping, reducing spillage, unnecessary cleanup, and time.

Whether in a metal fabrication shop, woodworking facility, or assembly plant, the Open-End Dump Hopper helps maintain a clean, organized workspace while improving productivity and safety. Give us a call to learn more!

Trustindex verifies that the original source of the review is Google. I requested a quote for a custom sized dump hopper for a very specific application and it was delivered quickly, and was of good quality. Justin was great to work with and was flexible on changing a few small items of the design that made it fit our purposes perfectly.Trustindex verifies that the original source of the review is Google. The product was delivered on time and is well built. Great folks and products.Trustindex verifies that the original source of the review is Google. Great company and easy to work withTrustindex verifies that the original source of the review is Google. Justin was great to talk to ,understood what we wanted and gave us an excellent product great experienceTrustindex verifies that the original source of the review is Google. This was my first purchase from Creekside. I purchased a heavy duty dump hopper That is definitely built to last. Yes, I could have saved a few hundred dollars shopping somewhere else, but I know this model is built to last. The gentleman I spoke with during my inquiry/ sale was very adamant about the quality in the materials and manufacturing of there products. I definitely recommend Creekside Manufacturing.Trustindex verifies that the original source of the review is Google. Creekside is great to work with! I have over a dozen of their trash hoppers and have never had any issues with them. I highly recommend them.Trustindex verifies that the original source of the review is Google. High quality, great customer service!Trustindex verifies that the original source of the review is Google. Great fabricator. Quality workmanship at reasonable prices.

Open-Ended Dumpsters Built for Manufacturing, Designed for Efficiency

When handling long, oversized materials, standard hoppers can slow down operations. That’s why manufacturers, warehouses, and fabrication shops rely on Open-End Dump Hoppers by Creekside Manufacturing: a purpose-built solution for efficiently managing scrap, bulk waste, and production materials that don’t fit in a traditional bin.

Whether you’re disposing of metal tubing, lumber, PVC pipes, or sheet goods, the open-ended design allows for hassle-free loading and unloading without constraints.

Available in standard height and low-profile models, these hoppers are designed in sizes to integrate into any workspace. The low-profile version is ideal for sliding under workbenches and machinery, keeping materials organized while maximizing floor space. The standard height model offers high-capacity dumping for bulkier loads, making for smooth waste management in high-volume operations.

If you need a self-dumping hopper with no sides and need something tailored to your workflow, we can customize these hoppers to fit your specifications!

With heavy-duty construction, forklift compatibility, easy dumping operations, and smooth-rolling casters, the Open-End Dump Hopper makes material transport and disposal effortless. Designed to boost efficiency in woodworking facilities, production plants, and industrial shops, this durable dumpster keeps your operation running smoothly.

Upgrade your material handling capabilities – and keep your employees happier – by contacting us to explore our standard models or discuss a custom-built hopper for your facility!

Order Your Open Self Dumping hopper Today!

Don’t wait – if you’re looking for a dump hopper near me, you’re in the right place.

Call Creekside Manufacturing to discuss the right model for you, find out why we stand behind our dumpsters 100%, and get the customer service you’ve been looking for. Get in touch to get started!

The self-dumping mechanism is activated by tripping a safety latch at the back of the hopper, making it simple and safe to unload materials without manual lifting.

An Open Ended Dump Hopper is a self-dumping industrial dumpster designed with open sides, allowing for easy loading and unloading of long or oversized materials. It generally has sleeves for forklifts on the bottom of the dumpster and a self-dumping mechanism that can be triggered from the ground or even forklift operator’s seat.

Absolutely. Our hoppers are designed for forklift transport, with reinforced forklift pockets for safe and easy lifting, moving, and dumping.

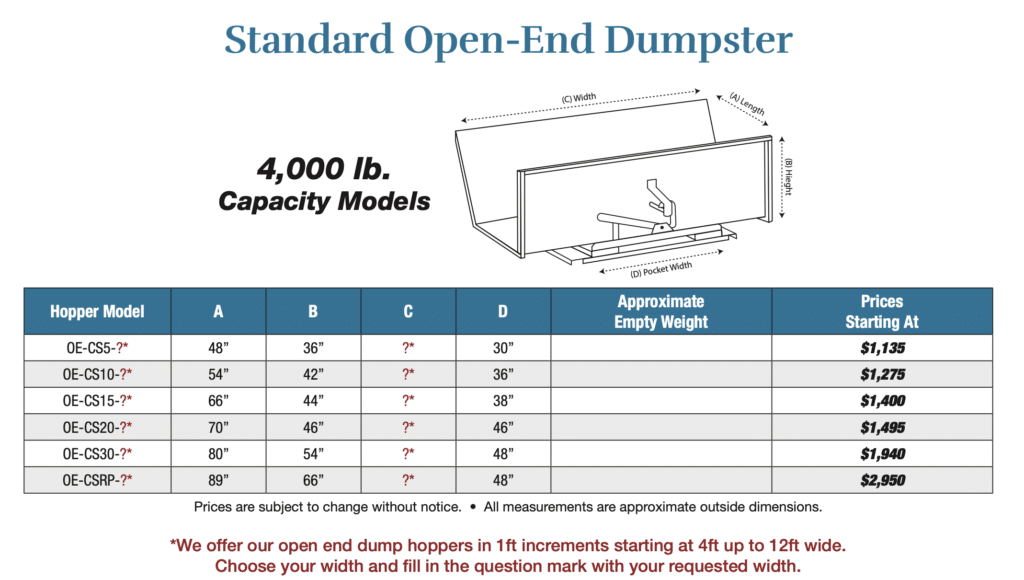

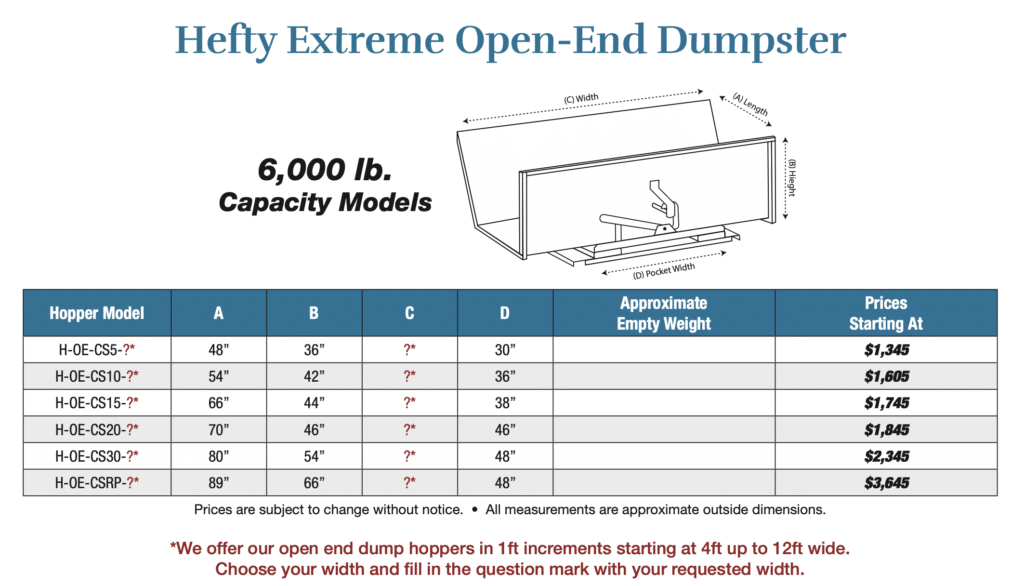

Our standard models handle over 4,000 lbs, while the Extreme model supports up to 6,000 lbs. Custom options are available for heavier-duty applications.

You can explore our standard models or request a custom build by contacting us. Our team will help you find the right hopper to optimize your workflow and improve material handling efficiency.