When it comes to managing waste and parts in your facilities efficiently, self dumping dumpsters, also known as self-dumping hoppers, stand out.

Their compatibility with forklifts and simple lever-operated dumping action address the hassle of waste disposal head-on. This article unpacks the practicality, safety, and economic advantage of our self dumping dumpster units, along with a comparison to traditional options and some real-world examples of self-dumping dumpsters in action.

Key Takeaways

- Self-dumping dumpsters, or self-dumping hoppers, are engineered to work seamlessly with forklifts and telehandlers to provide a more efficient waste management system than traditional dumpster methods, with customizable options like low-profile designs and stackable units for various industrial environments.

- Our dumpsters are versatile tools for parts storage, in enhancing workflows at manufacturing workstations, and in creating central waste stations. Ultimately, they’re designed to streamline waste management and improve safety and workspace organization!

- Steel self-dumping dumpsters offer significant advantages such as time-saving efficiency in waste management processes, enhanced safety features to reduce workplace injuries, and improved profit margins through reduced labor costs and increased productivity.

Understanding Self Dumping Dumpsters

Far from being just a metal container, a self-dumping dumpster, commonly known as a ‘hopper’, serves a strategic and profitable purpose in material handling.

Designed to work in harmony with forklifts or telehandlers at your facility or on the job-site, a self-dumping dumpster from Creekside Manufacturing can transform the way you manage waste. Made possible by our smartly engineered rocker system, dump hoppers can be easily emptied just by activating a lever, offering a more efficient alternative to traditional trash bins or small dumpsters.

Manufacturing facilities and construction sites, among other industrial settings, have found immense use for our steel or aluminum self dumping hoppers. What’s more, our steel self dumping hopper offer a high degree of customization to cater to your specific needs. They:

- low-profile designs for space-constrained environments

- are stackable for optimized storage

- are available in a variety of materials like stainless steel or aluminum to withstand the rigors of different industrial operations

- are water-tight and useful for food disposal

- and can be customized to your needs! In fact, we love building custom dumpsters!

How Our Customers Use Self-Dumping Dumpsters

The versatility of self-dumping dumpsters is evident in the diverse ways our customers use them. Some common uses include:

- Parts storage

- Manufacturing workstations

- Central waste stations

- Under workbenches

These dumpsters are redefining efficiency and safety in waste management.

For Parts Storage

Our self-dumping dumpsters have even employed across a diverse array of industries to facilitate parts storage.

Why? Because our dumpsters and hoppers are stackable, they’re a great alternative to pallet racks. And because they easily handle materials in bulk, they can be far more efficient than hand-moving wood, parts, etc. Ultimately if your employees are working with many small parts repetitively, our dumpsters are versatile in storing a wide range of parts or tools. They’ve been used for:

- automotive parts

- plastics and vinyl manufacturing stock

- raw or finish wood storage in wood shops

- and more

Next To Manufacturing Workstations for Scraps

Incorporating self-dumping dumpsters into your manufacturing environment can enhance your team’s workflow and improve efficiency, creating a more pleasant work environment, and ultimately contributing to increased profitability.

Our dumpsters are great next to or beneath manufacturing workstations, allowing your team to quickly toss scraps or trash into the large open mouth without worrying about repeatedly carrying trash cans elsewhere in the facility.

Common types of waste produced at manufacturing workstations that can be effectively handled using self-dumping dumpsters include construction debris, scrap metal for recycling, plastic millings, metal millings or metal scraps, cardboard waste, other bulk materials, and even chemicals.

As a Central Waste Station

In environments where material is moving around consistently, and heavy-duty usage of trash is the norm, handling bulk material can be a real waste of time, especially when dealing with heavy loads.

As central waste stations, self-dumping dumpsters optimize the entire waste management process within a facility, ensuring efficient operation and waste disposal. You may not be ready for a dmp hopper at every workstation, but adding a single self-dumping hopper to a central point can be a real time-saver. This means employees can take their trash cans to a central self-dumping dumpster, which can be taken outdoors by forklift once a day.

Utilizing a self-dumping dumpster as a central waste station provides improved efficiency, reduced labor costs, and even tailored features to address your operational requirements.

Beside or Under Workbenches

The compact design of our low profile dumpsters allows them to fit under workbenches, providing a practical solution for the storage, sorting, and collection of materials in close proximity to the work area.

Utilizing self-dumping dumpsters beneath workbenches can enhance manufacturing facilities by:

- Streamlining waste gathering and storage

- Improving efficiency and safety

- Promoting a tidy workspace

- Minimizing clutter

- Eliminating the necessity for manual dumping

- Fostering a more organized work environment.

Low-profile self-dumping dumpsters are specifically engineered to be emptied using a fork truck with forklift pockets. The dumping process is as simple as pulling a lever from the seat of the fork truck, causing the hopper to tip and release its contents. Once the dumping is complete, the unit automatically returns to an upright and locked position.

Advantages of Using Self Dumping Dumpsters

Our self-dumping dumpsters boast three significant benefits for businesses: they save time, improve workplace safety, and contribute to better profit margins.

Time-Saving Efficiency

Self-dumping dumpsters contribute to time savings and increased efficiency in the workplace by:

- promoting organization

- reducing the need for manual labor in waste handling

- optimizing storage space

- streamlining waste management processes

- helping eliminate the time spent on cleaning up materials such as scraps and dust

This ultimately leads to enhanced productivity.

Enhanced Safety and Lowered Liability

The safety benefits that self-dumping dumpsters provide are substantial. They enhance workplace safety by offering a more efficient and pleasant work process, reducing the potential for injuries related to moving or emptying large trash cans (or whatever funky way you’ve been handling your trash).

The design of our self-dumping dumpsters incorporates various safety measures, such as:

- Ensuring the hopper can dump up to 30 degrees below horizontal for complete emptying

- A safety chain that can be secured to the forklift mast

- A self-locking safety latch

By streamlining your material handling equipment, manufacturing plants can cut back on safety risks for employees, plus reduce liability exposure for the business.

Better Margins

Improved waste disposal efficiency and reduced labor time in material collection and dumping, courtesy of self-dumping dumpsters, can significantly enhance a business’s profit margins!

Effective use of self-dumping dumpsters for waste management can result in financial advantages, including decreased expenses for waste hauling and disposal, reduced labor costs, and potential savings through waste minimization strategies. Employees are more likely to properly use recycling bins or dumpsters when they know they have less “work” to move it around at the end of the day.

By enabling employees to concentrate on more essential responsibilities – like building your end-product – our dumpsters enhance employee productivity.

Their durability and capacity for handling bulk items make them a cost-effective long-term investment, capable of withstanding rigorous daily use.

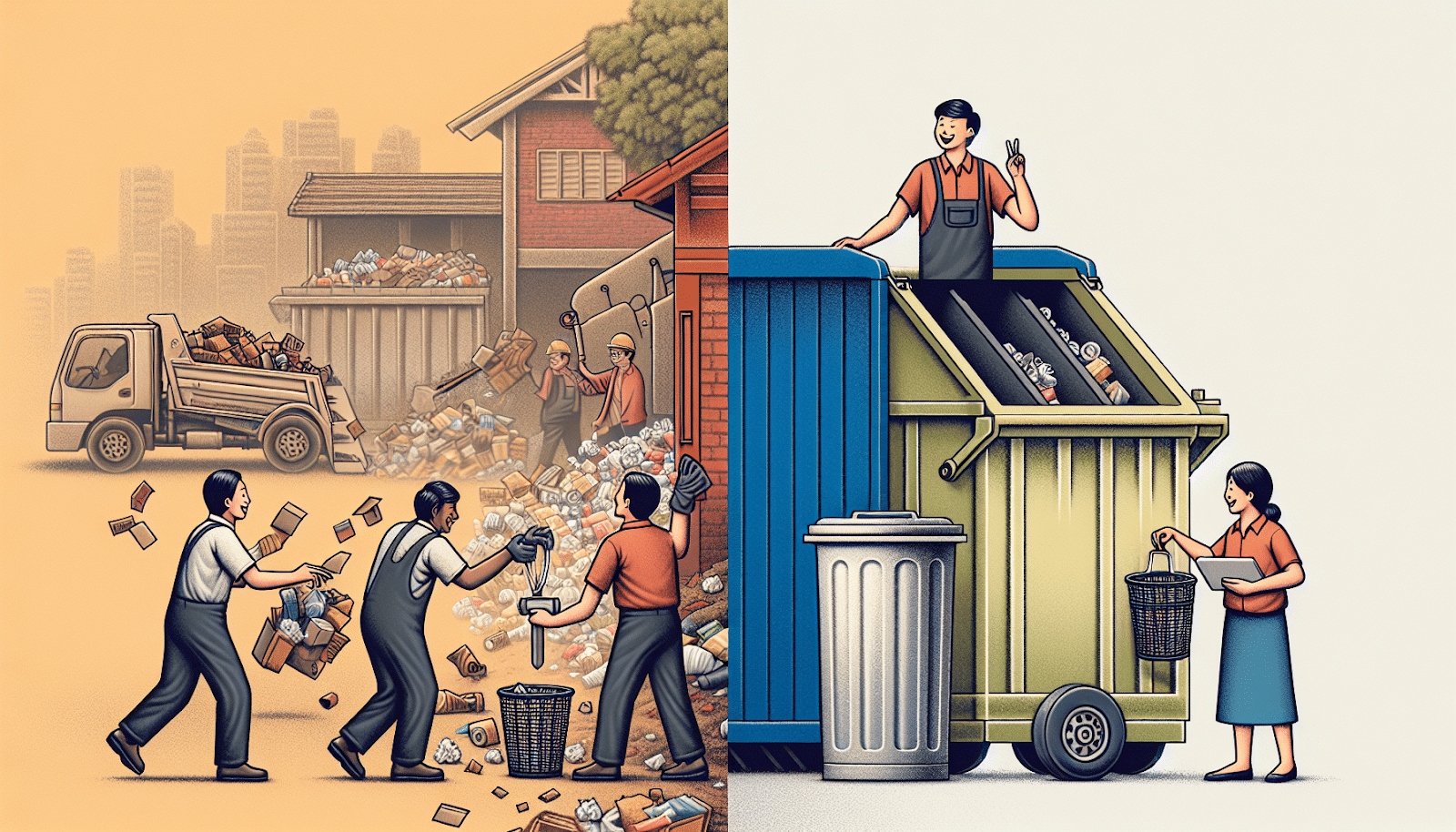

Comparison: Self Dumping Dumpsters vs. Traditional Dumpsters

Despite both serving the fundamental purpose of waste management, self-dumping dumpsters stand in stark contrast to traditional dumpsters. Self-dumping dumpsters outshine their traditional counterparts in terms of efficiency, safety, and profitability.

Self-dumping dumpsters offer several benefits, including:

- Improved efficiency that reduces labor costs

- Mechanical operation that reduces safety risks

- Customizable options to meet specific operational requirements

The advantages of self-dumping dumpsters over traditional dumpsters are clear. From improved efficiency and safety to better profit margins, our dumpsters are transforming waste management across various industries.

If you’re looking to improve efficiency, safety, and profitability in your waste management processes, it’s time to consider integrating self-dumping dumpsters into your operations. They’re not just a practical solution for waste management but a strategic tool that can propel your business forward.

As a self-dumping hopper manufacturer for nearly two decades, call Creekside Manufacturing today for updated pricing and to talk more about customizable options!

Frequently Asked Questions

What is a self-dumping hopper?

A self-dumping hopper is a large metal container designed to work with forklifts or telehandlers, allowing for easy emptying with the use of a lever. It offers an efficient alternative to traditional trash bins.

How do self-dumping hoppers create time-saving and increased efficiency in the workplace?

Self-dumping hoppers contribute to time-saving and increased efficiency in the workplace by promoting organization, reducing manual labor in waste handling, and optimizing storage space. This increases overall productivity and reduces operational costs.

What safety features are integrated into the design of self-dumping dumpsters?

Self-dumping dumpsters are designed with safety features such as a secured safety chain, the ability to dump at a safe angle for complete emptying, and emphasis on safe operational practices.

How do self-dumping dumpsters compare to traditional dumpsters?

Self-dumping dumpsters outperform traditional dumpsters by improving efficiency, safety, and profitability with their compact design and mechanical operation. They can even be suitable for confined spaces and enable cost-effective disposal of different materials.